Table of Contents

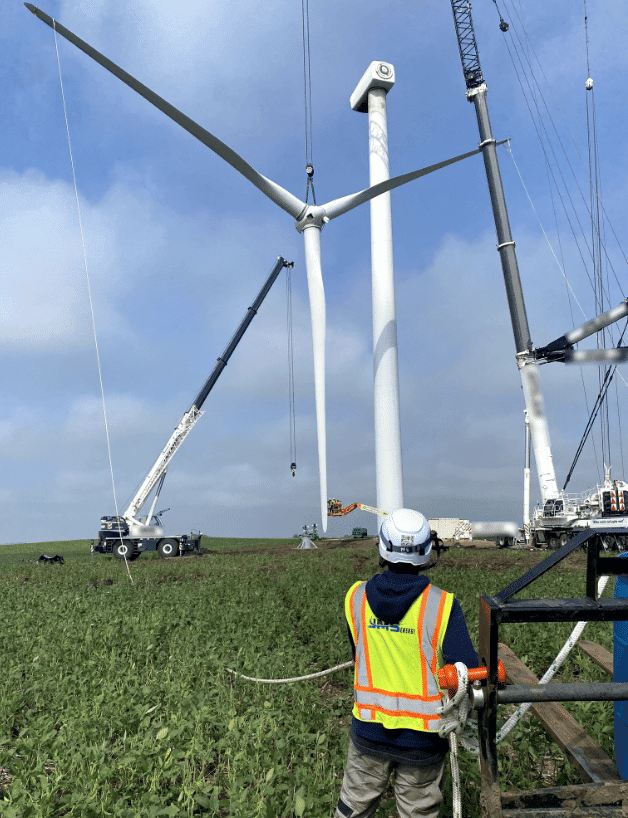

Wind farm construction projects are central to the global shift towards renewable energy. These projects provide clean, sustainable energy to communities while reducing reliance on fossil fuels. At JMS Energy, we specialize in all stages of wind farm construction, including two critical phases: grid connection and commissioning, as well as long-term operations and maintenance (O&M). This blog will focus on these essential components, detailing the services we offer to ensure the continued success and efficiency of wind farm projects.

1. The Importance of Grid Connection in Wind Farm Construction Projects

The grid connection process links the newly constructed wind farm to the local or regional power grid, enabling the distribution of generated electricity. This step is crucial, as it determines the reliability and efficiency of power transmission. Proper grid connection requires meticulous planning and coordination with local utilities, as well as adherence to stringent regulatory standards.

At JMS Energy, we work closely with utility companies and regulatory agencies to ensure a smooth and compliant grid connection. Our team conducts thorough assessments to determine the best connection points, accounting for factors such as voltage compatibility, transmission infrastructure, and grid capacity. This planning helps us minimize energy losses and optimize the wind farm’s overall output.

Additionally, our team installs the necessary transformers, switchgear, and protection equipment to facilitate safe and reliable power transfer from the turbines to the grid. We implement advanced monitoring systems to track performance and ensure that the connection meets regulatory requirements. These systems also provide critical data, enabling proactive maintenance and swift response to any issues that arise.

2. The Commissioning Phase: Testing and Optimization

Once the grid connection is established, the commissioning phase begins. Commissioning involves testing every aspect of the wind farm to ensure that all components function correctly and that the system operates at optimal efficiency. This process includes individual turbine testing, electrical system checks, and overall system performance assessments.

JMS Energy’s commissioning team follows a rigorous testing protocol to confirm that each turbine is functioning according to design specifications. We conduct performance tests under various conditions to assess the turbines’ responsiveness to different wind speeds, loads, and grid demands. Our technicians monitor critical factors such as rotor speed, blade pitch, and energy output, ensuring that the turbines are ready for consistent operation.

We also prioritize safety during the commissioning phase. Our team inspects all safety systems, including braking mechanisms, emergency stop controls, and protective relays. By verifying these systems, we can ensure that the wind farm operates safely and effectively under all conditions. Once testing is complete, we provide a comprehensive report detailing the commissioning results, along with any recommendations for further optimization.

3. Operations and Maintenance for Long-Term Efficiency

After the commissioning phase, the focus shifts to the ongoing operations and maintenance (O&M) of the wind farm. O&M is essential for maximizing the lifespan of the turbines and maintaining optimal energy production. At JMS Energy, we offer comprehensive O&M services that include regular inspections, performance monitoring, and preventive maintenance.

Routine inspections are a cornerstone of our maintenance approach. Our technicians conduct detailed visual and mechanical inspections to identify signs of wear, damage, or potential issues before they escalate. We inspect components such as blades, gearboxes, and electrical systems, ensuring that each part is in good condition and operating efficiently. Regular inspections help us address minor problems proactively, reducing the risk of costly downtime.

Our performance monitoring services involve tracking each turbine’s output and comparing it to expected performance benchmarks. We use sophisticated data analytics to detect anomalies, such as drops in power output or changes in vibration patterns, that may indicate underlying issues. By monitoring performance in real-time, we can make adjustments to optimize turbine efficiency and prolong the lifespan of each unit.

4. Preventative and Predictive Maintenance: Minimizing Downtime

Preventative maintenance plays a vital role in reducing unplanned outages and prolonging the operational life of wind turbines. At JMS Energy, we schedule regular maintenance activities based on each turbine’s operational history, environmental conditions, and manufacturer recommendations. Preventative tasks include lubrication, component cleaning, and part replacements as needed.

In addition to preventative maintenance, we offer predictive maintenance services that use advanced diagnostic tools to anticipate potential failures. For example, we conduct vibration analysis, oil analysis, and thermal imaging to detect early signs of component wear or fatigue. By identifying issues before they lead to breakdowns, we can schedule repairs during planned maintenance windows, minimizing the impact on overall energy production.

Our team also maintains an inventory of critical spare parts to facilitate quick repairs, ensuring that the wind farm remains operational with minimal downtime. We are committed to providing efficient and cost-effective maintenance solutions that support the long-term success of our clients’ wind farm projects.

Why JMS Energy is Your Partner for Grid Connection, Commissioning, and Maintenance

Wind farm construction projects are complex, and each stage—particularly grid connection, commissioning, and maintenance—requires specialized expertise. At JMS Energy, we bring extensive experience and a comprehensive approach to every project, focusing on quality, safety, and efficiency. Here’s why you should choose JMS Energy for your wind farm needs:

- Expert Technicians: Our team includes certified technicians with deep expertise in grid connection, commissioning, and maintenance. We leverage the latest technology to ensure your wind farm operates at peak efficiency.

- Advanced Monitoring Systems: JMS Energy utilizes state-of-the-art monitoring systems to track performance in real-time, enabling us to address issues promptly and optimize overall energy production.

- Commitment to Sustainability: We are dedicated to promoting renewable energy and helping our clients reduce their carbon footprint. Our maintenance practices are designed to extend turbine lifespan and enhance energy efficiency, contributing to a greener future.

Frequently Asked Questions: Wind Farm Construction Projects

Q: How long does the commissioning phase take?

A: The commissioning phase varies depending on the size and complexity of the wind farm. On average, it takes between two and six weeks to complete all tests and finalize the commissioning process.

Q: What is the difference between preventative and predictive maintenance?

A: Preventative maintenance involves regularly scheduled tasks to prevent equipment failures, while predictive maintenance uses diagnostic tools to detect potential issues before they become serious problems. Both approaches help minimize downtime and optimize turbine performance.

Q: How often do wind turbines need maintenance?

A: Wind turbines typically require maintenance two to three times per year, though this can vary based on environmental conditions and turbine usage. JMS Energy offers customized maintenance schedules to meet each client’s needs.

By focusing on effective grid connection, thorough commissioning, and comprehensive maintenance, JMS Energy ensures the long-term success and efficiency of wind farm construction projects. Contact us today to learn more about our wind farm services and how we can help you achieve your renewable energy goals.