Electric panel upgrades are essential for ensuring the safety, efficiency, and reliability of your home’s electrical system. If you’re considering an upgrade or want to learn more about why JMS Energy is the ideal choice, this FAQ-style article will guide you through everything you need to know.

Table of Contents

What Sets JMS Energy Apart in Electric Panel Upgrades?

JMS Energy has earned its reputation as a leader in electric panel upgrades through a commitment to quality, safety, and customer satisfaction. Their approach is rooted in a deep understanding of modern electrical systems and the latest technological advancements. With years of experience in energy solutions, JMS Energy ensures that all installations meet local codes and regulations, which translates into peace of mind for clients.

Several standout qualities mark JMS Energy’s uniqueness in the market. Firstly, their team of well-trained professionals brings a wealth of knowledge and expertise to every project, handling complex tasks with ease. Additionally, their dedication to using the highest quality materials ensures durability and long-term reliability.

Why Are Electric Panel Upgrades Necessary?

An electric panel, often known as a breaker box, serves as the heart of your home’s electrical system. Over time, increased electrical demands and outdated panels can lead to inefficiency or even dangerous conditions. This is where JMS Energy steps in with modern solutions that accommodate current technological advancements and safety standards.

Upgrading your electric panel can solve issues such as flickering lights, frequent breaker tripping, and insufficient power supply for modern appliances. JMS Energy excels at assessing these needs and providing tailored upgrades that cater to individual household demands.

How Do JMS Energy’s Services Ensure Safety and Compliance?

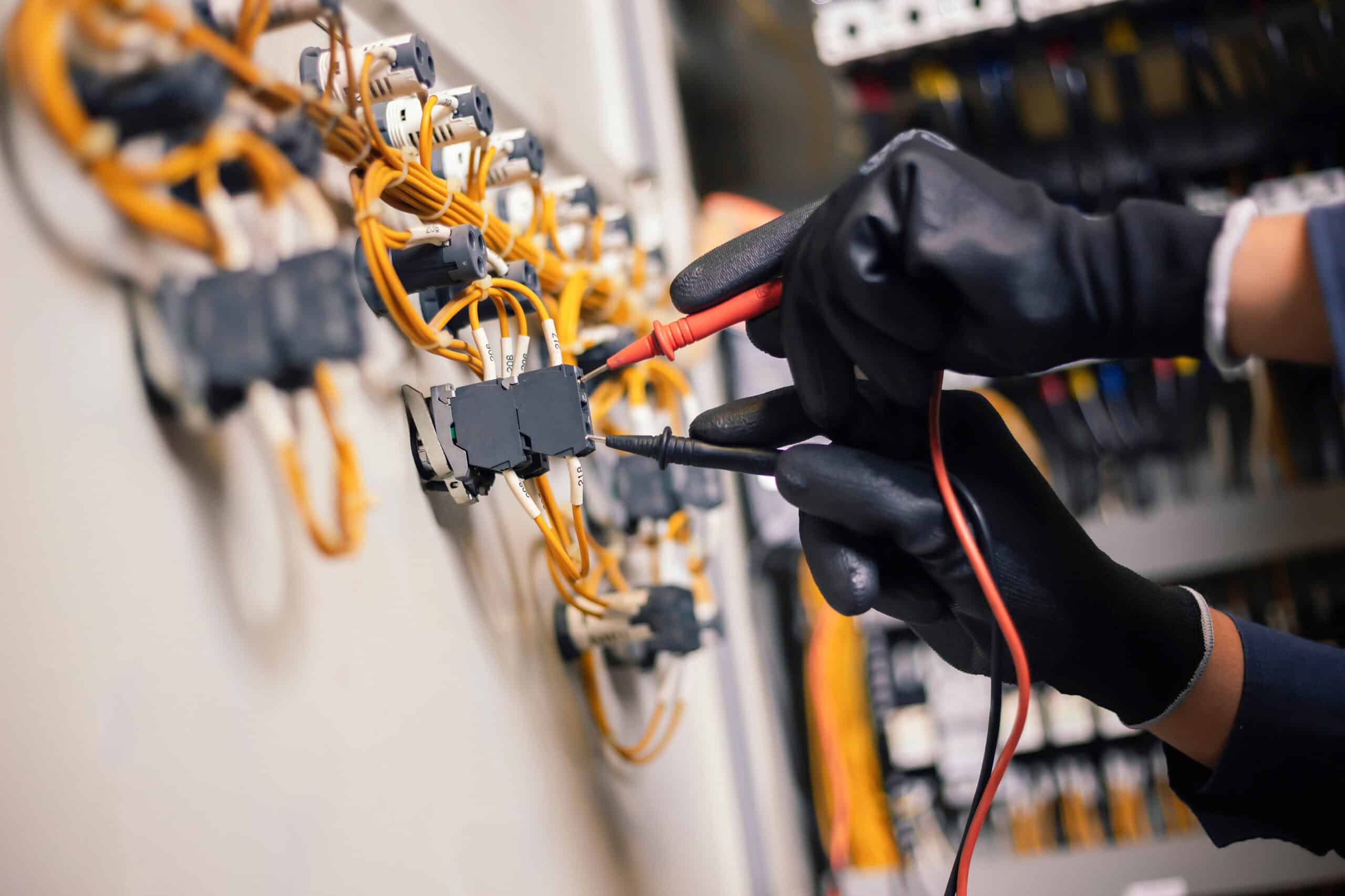

Safety is JMS Energy’s top priority. They employ a meticulous process to verify that every electrical panel installation or upgrade is compliant with local electrical codes and safety standards. This not only protects your home but also enhances the insurance compliance of your property.

The company’s engineers and technicians are continually updated on codes and standards, ensuring that all installations are conducted with precision and care. This dedication to safety minimizes risks such as electrical fires, which can arise from outdated or improperly installed panels.

What Is the Process for an Electric Panel Upgrade with JMS Energy?

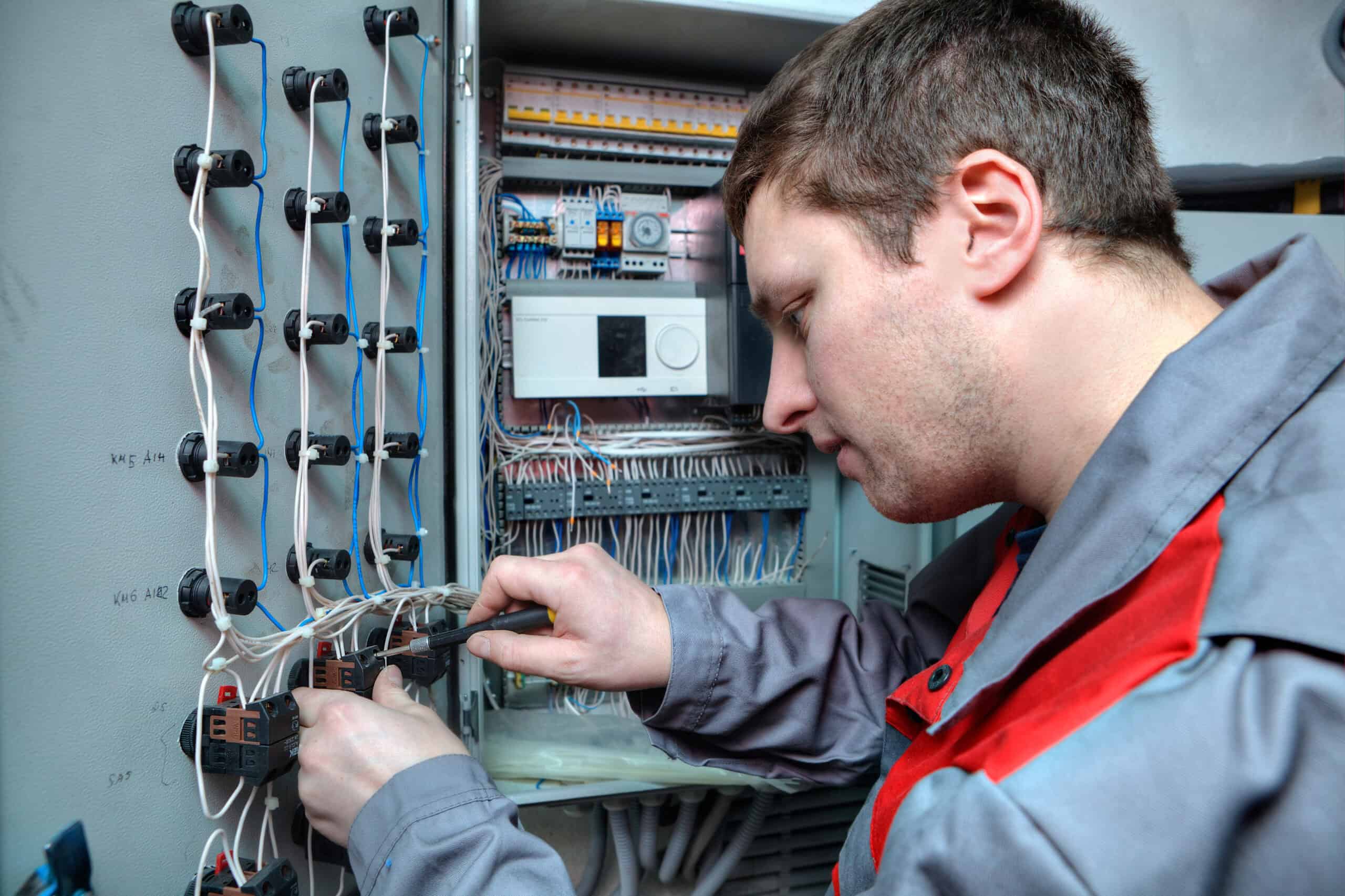

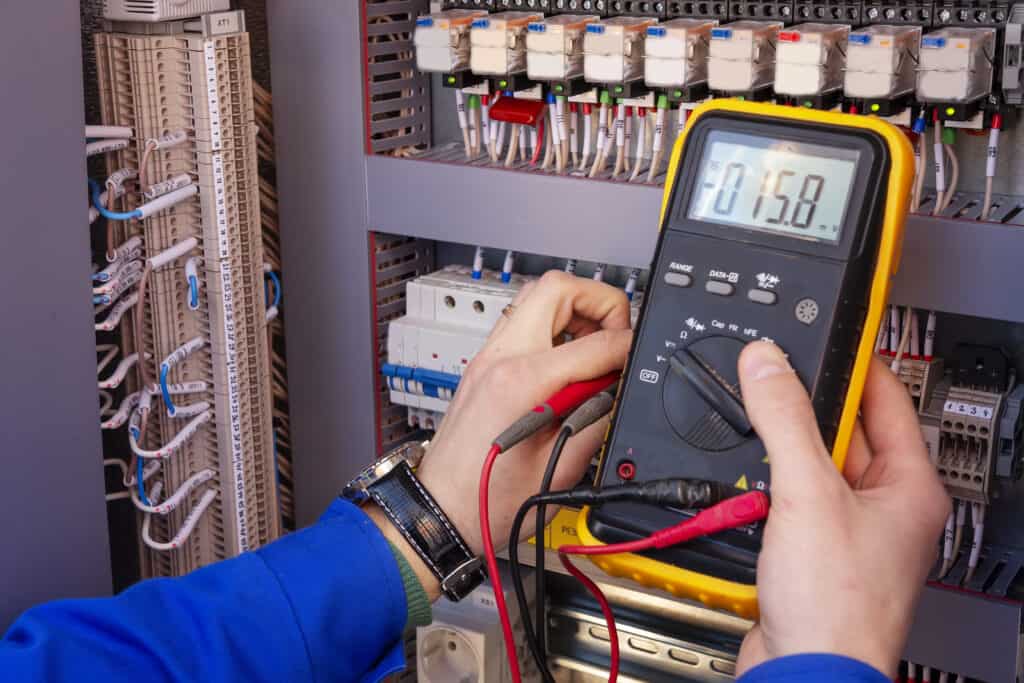

JMS Energy offers a streamlined, customer-friendly process for electric panel upgrades. It begins with a comprehensive assessment of your current electrical system and household power needs. Based on their evaluation, they provide a detailed plan and quotation, ensuring transparency and understanding of the scope of work.

The upgrade itself is carried out by skilled technicians, who minimize disruption and maintain a clean work environment. Post-installation, JMS Energy conducts rigorous testing to ensure your new panel operates optimally, providing you with a reliable and efficient electrical system.

How Does JMS Energy Integrate Sustainable Practices into Their Services?

Sustainability is a core value at JMS Energy, evident in their integration of cutting-edge energy solutions. Their expertise in areas like wind energy and battery energy storage systems (BESS) enhances their electric panel upgrade services. By positioning clients to accommodate renewable energy sources and efficient storage systems, JMS Energy delivers not just an upgrade but a future-ready solution.

Their services provide a pathway to incorporating sustainable energy options, allowing homeowners to reduce their carbon footprint and potentially decrease energy costs. The alignment of electric panel upgrades with renewable energy solutions represents JMS Energy’s forward-thinking approach.

What Are the Long-Term Financial Benefits of an Electric Panel Upgrade?

Upgrading your electric panel with JMS Energy is an investment that can lead to considerable long-term savings. Modern panels improve the efficiency of your home’s electrical system, potentially reducing energy bills over time. Additionally, a new panel can increase your home’s value, a crucial factor if you plan to sell in the future.

JMS Energy ensures that installations not only meet but exceed current standards, often reducing the need for frequent repairs or replacements. By choosing JMS, customers benefit from durable solutions that stand the test of time, contributing to financial savings.

How Does JMS Energy Address Unique Customer Needs?

Every home has distinct electrical requirements, and JMS Energy excels in offering personalized solutions. Their team takes the time to understand each client’s specific needs and tailor their services accordingly. Whether it’s accommodating additional appliances, planning for future home expansion, or integrating renewable energy systems, JMS Energy provides custom solutions that cater to diverse demands.

Their commitment to personalization ensures that each electric panel upgrade aligns perfectly with the homeowner’s current and future requirements, offering flexibility and adaptability.

What Role Does Customer Service Play in JMS Energy’s Approach?

Exceptional customer service is a hallmark of JMS Energy’s operations. From the initial consultation to post-installation support, JMS Energy focuses on building strong, trusting relationships with their clients. This client-centric approach guarantees open communication, transparency, and responsive service.

Feedback from many satisfied customers attests to JMS Energy’s dedication to service excellence, making them a preferred choice for electrical upgrades. Their commitment to addressing concerns, answering questions, and providing professional guidance cultivates a supportive experience throughout the upgrade process.

Can JMS Energy Handle Both Residential and Commercial Electric Panel Upgrades?

Yes, JMS Energy is adept at managing both residential and commercial electric panel upgrades. Their expansive expertise extends beyond homes to encompass businesses that may require more robust electrical solutions. From small offices to substantial commercial facilities, JMS Energy has the capability and experience necessary to handle projects of all sizes and complexities.

This adaptability across various sectors highlights JMS Energy’s versatile approach and ability to cater to diverse customer needs, further emphasizing their stature as industry leaders.

What Other Services Complement Electric Panel Upgrades?

Beyond electric panel upgrades, JMS Energy offers a suite of services that complement and enhance their primary offerings. These include battery energy storage systems (BESS), communication infrastructure solutions, and wind energy systems. By providing these additional services, JMS Energy ensures comprehensive energy solutions that meet modern demands.

Their multi-faceted expertise empowers clients with interconnected systems that work seamlessly together, offering both efficiency and environmental benefits.

Conclusion

Choosing JMS Energy for your electric panel upgrade means opting for quality, safety, and an unwavering commitment to customer satisfaction. Their expert team, sustainable practices, and comprehensive approach make them standout leaders in the field.

For those seeking reliable, efficient, and future-ready electrical solutions, JMS Energy delivers with professionalism and excellence, ensuring your home or business has the power it needs to thrive.ExpandGoodBad