When it comes to “mv construction,” selecting the right partner can dramatically influence the success, efficiency, and safety of your medium voltage (MV) infrastructure projects. JMS, with decades of industry experience, sets itself apart as a leading provider of full-service MV construction solutions. In this comprehensive FAQ, we’ll explore why JMS Energy stands out, the depth of their expertise, and what you can expect when entrusting your MV construction needs to their capable hands.

Table of Contents

What is MV Construction and Why is it Critical in Energy Infrastructure?

MV construction refers to the design, installation, and maintenance of medium voltage electrical systems—typically ranging from 1kV to 69kV. These systems are central to the transmission and distribution of electrical power, whether in wind farms, utility substations, or industrial facilities. The reliability and safety of these systems are absolutely essential, supporting everything from renewable energy integration to large-scale industrial operations.

JMS specializes in the complete lifecycle of MV systems—starting from meticulous planning and design to energization and ongoing support. Their deep knowledge and experience ensure that projects are executed with strict adherence to safety, industry standards, and client-specific requirements.

How Does JMS Approach Safety and Reliability in MV Construction Projects?

Safety is the foundation upon which all successful MV construction projects are built. JMS has an impeccable safety record, underpinned by rigorous training, proactive risk assessments, and strict adherence to OSHA and NFPA 70E standards. Their safety-first culture permeates every job site and every phase of construction.

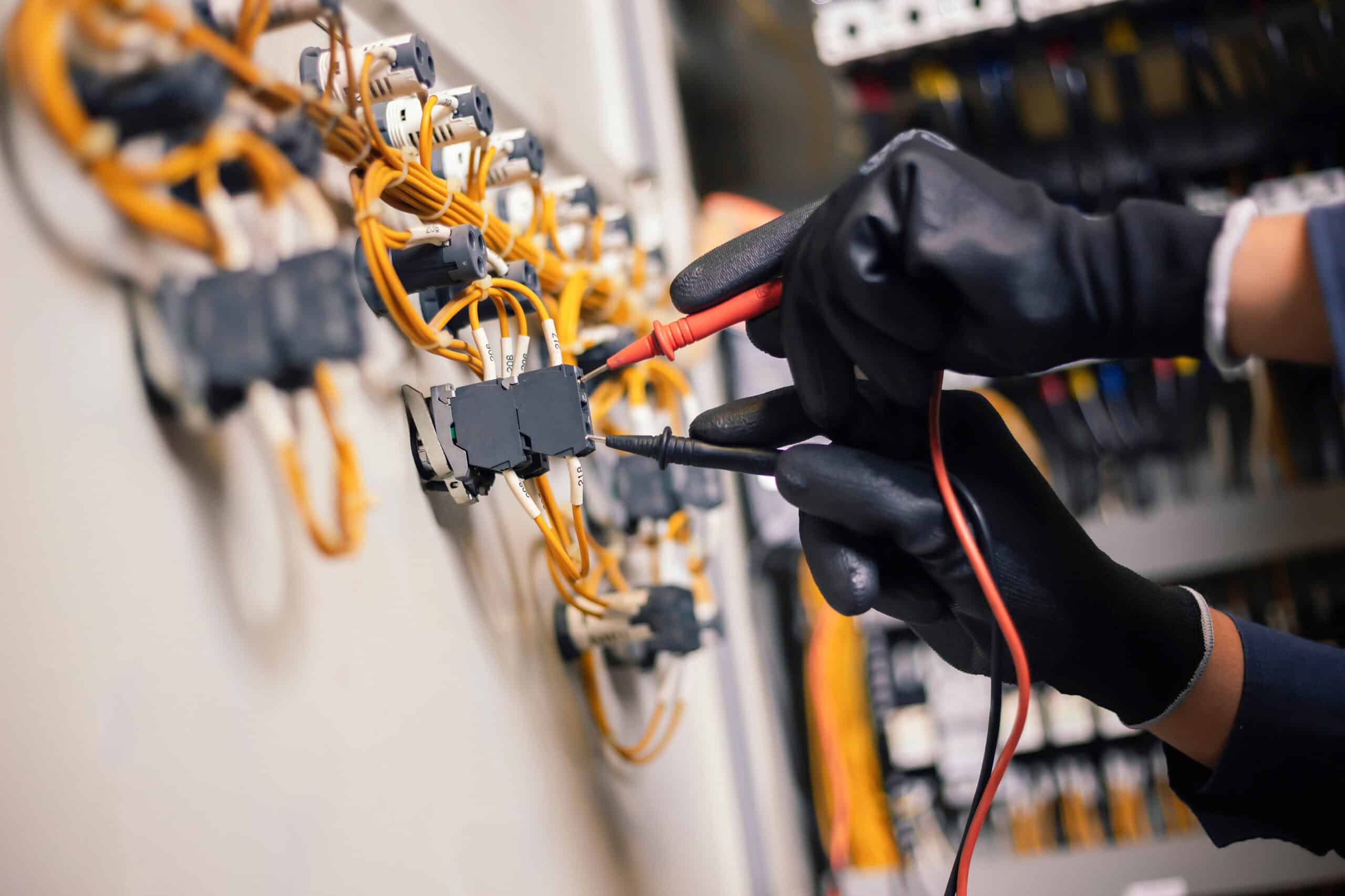

Reliability, as delivered by JMS, grows directly out of this safety culture. Every crew member is highly trained and certified, ensuring that installations are not just compliant, but constructed to withstand demanding operational stresses over time. From cable trenching to switchgear installations, JMS’s best practices minimize the risk of outages or system failures, which is crucial for clients relying on uninterrupted power delivery.

What Distinguishes JMS’s Technical Capabilities in MV Construction?

JMS Energy invests heavily in both human expertise and cutting-edge technology. With a skilled workforce that includes licensed electricians, project managers, and specialized engineers, JMS can address challenges ranging from underground duct banks to overhead line work. Their services cover every critical phase:

- Design and Engineering: Custom MV solutions, tailored to the site’s unique requirements, ensure optimal performance and compliance.

- Procurement: JMS manages the sourcing of all critical components (cables, switchgear, transformers), ensuring both quality and timeliness.

- Installation: Precision installation of medium voltage cables, terminations, splices, switchgear, protective relays, and grounding systems.

- Testing and Commissioning: Comprehensive MV system testing ensures operational readiness and regulatory compliance.

- Maintenance and Upgrades: Proactive system maintenance and efficient upgrades to support lifecycle management.

Moreover, JMS leverages advanced tools—like real-time system monitoring and diagnostic equipment—to verify every installation before commissioning. This attention to detail sets them apart and reduces costly delays for clients.

What Experience Does JMS Bring in Renewable Energy MV Construction?

Few sectors have as strong a demand for dependable MV construction services as the renewable energy industry, especially wind power. JMS Energy has established itself as a leading partner for wind farm developers across the country. According to JMS’s wind energy sector page, their teams have contributed to more than 80 wind energy projects, delivering not only MV construction but also comprehensive electrical infrastructure services.

Their wind energy expertise covers:

- Installation of collection systems, including MV underground and overhead lines that connect turbines to substations.

- Construction and commissioning of substations, integrating medium voltage assets seamlessly with high voltage grids.

- Assistance with interconnection, supporting clients as they navigate utility and regulatory requirements.

This hands-on experience means JMS deeply understands the logistical, regulatory, and technical challenges unique to renewable MV projects—and is always prepared to exceed expectations.

How Does JMS Ensure Scalability and Timeliness in MV Construction Projects?

Large-scale infrastructure projects demand scalability and precise scheduling. JMS Energy’s project management framework is specifically designed to handle the logistical complexities of MV construction at scale.

- Resource Allocation: With a broad workforce and fleet of specialized vehicles and tools, JMS can quickly ramp up resources to meet aggressive construction deadlines.

- Supply Chain Proficiency: JMS maintains strong relationships with vendors and manufacturers, sharply reducing lead times on critical components.

- Integrated Project Management: By deploying advanced scheduling and communication tools, JMS keeps every stakeholder up-to-date, reducing delays and keeping projects on track.

This capability is particularly valuable for clients developing wind or solar farms that must be commissioned rapidly to capture renewable energy incentives or meet power purchase agreement timelines.

What Long-Term Support Services Does JMS Provide After Construction is Completed?

MV construction does not end at energization. JMS Energy offers a suite of long-term support services to maximize system longevity and minimize operational risks:

- Preventative Maintenance Programs: Comprehensive inspection and testing protocols identify potential weak points before they become failures.

- Emergency Response: JMS maintains an emergency response division, providing swift troubleshooting and repair in case of outages or equipment failures.

- System Upgrades and Expansions: As power demands grow or technology evolves, JMS supports seamless upgrades and expansion projects.

Clients benefit from ongoing access to the same experts who built their systems, ensuring continuity, reliability, and confidence in their MV infrastructure.

How Do Clients Benefit Financially from JMS’s MV Construction Expertise?

While lowest upfront price is tempting, true value in MV construction lies in lifelong system cost savings, uptime, and efficiency. JMS’s commitment to quality and precision yields real financial benefits:

- Reduced Downtime: Rigorous system testing and best-in-class installation practices cut the risk of outages, which can cost industrial or renewable clients millions in lost power generation.

- Operational Efficiency: JMS’s designs often include energy monitoring tools and smart controls, which help reduce power losses and operational inefficiencies.

- Minimized Rework: Investing in experienced partners like JMS means jobs are done right the first time, minimizing expensive rework or legal liabilities.

The result is a higher return on investment for every dollar spent on MV construction.

Why Should You Choose JMS for Your Next MV Construction Project?

Selecting JMS as your MV construction partner means choosing a track record of excellence, safety, and innovative problem solving. Whether your project is a complex wind farm, a utility substation upgrade, or a new industrial facility, JMS’s experienced teams and sophisticated project management approach ensure a successful outcome.

Their unique blend of technical know-how, scalability, commitment to safety, and in-depth renewable energy experience positions them as the go-to provider for anyone seeking the best in MV construction.

To learn more or start planning your next project, visit the JMS website or contact their team directly.

In the evolving world of energy infrastructure, having an MV construction expert like JMS is not just an advantage—it’s a necessity for building resilient, high-performance power systems that stand the test of time.